A whole range of new borehole tools have been developed and introduced into the marketplace for improved reservoir monitoring and production. A borehole tool that could look deeper into the formation away from the borehole would be of great benefit for this purpose.

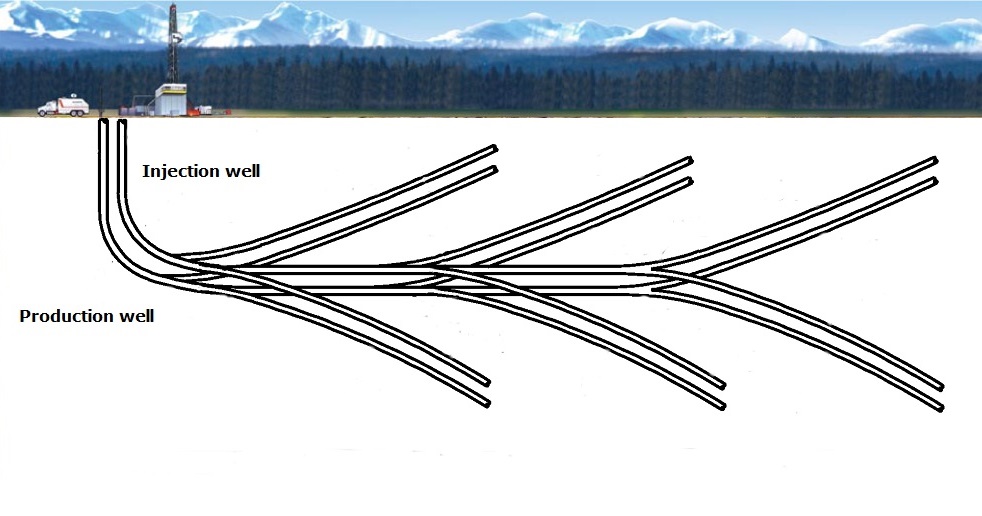

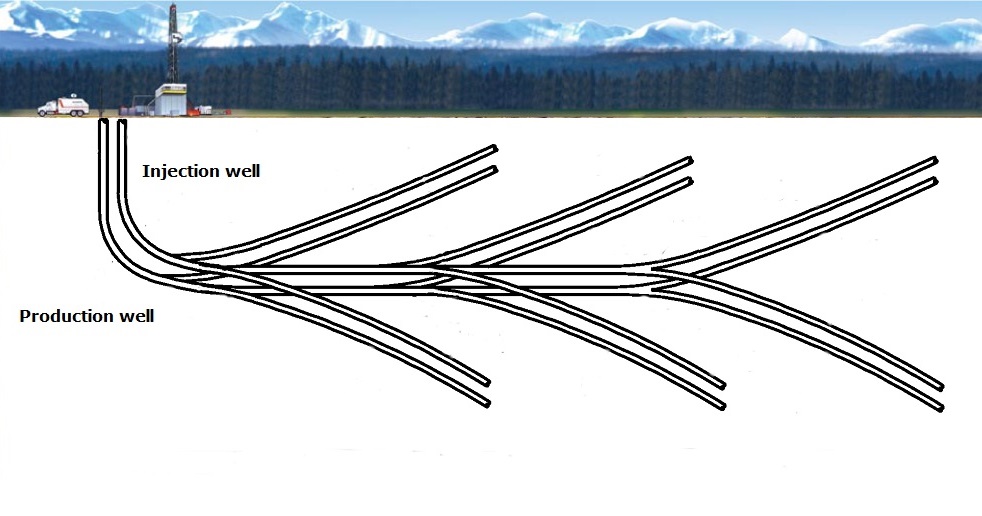

More efficient and smarter technology should make production of petroleum cleaner and more durable and reduce the emission of greenhouse gases. This calls for improvements in SAGD operations, especially in well configurations. If the extraction of oil-sand can be accelerated and the number of SAGD wells can be reduced, a great reduction in greenhouse gases can be achieved.

When drilling SAGD wells in fewer numbers and in alternate configurations, such as fishbone patterns and trenching, precision in the locations is crucial. The monitoring of drilling wells and fractures is an essential activity that requires an accurate borehole tool. Preferrably this tool can measure distances and angles of sidetracks to adjacent main SAGD wellbores as well as image developing fractures away from SAGD wellbores. A simple Measure-While-Drilling tool that does directional drilling only is not enough for this purpose. Deploying the tool after drilling of the main SAGD backbone and during the drilling of the ‘fishbone’ sidetracks can generate ultimate precision in the drilling geometry. In post-drilling operations, reservoir production can be monitored between the backbone and fishbones using timelapse

3D Borehole Radar (BHR) imaging. With the BHR tools, the desired production enhancement of SAGD can be made efficient and durable.

Oil sand exploration can benefit from an imaging method that detects interfaces of SAGD wellbores and fractures. Ground Penetrating Radar (GPR), as an EM-based wavefield method, is a good candidate having an imaging resolution ranging from millimeter-scale to meter-scale, depending on source frequency. Penetration depth is inversely proportional to the source frequency and ranges from tens of meters to centimeters.

As such, it starts imaging where other borehole tools stop.

The 3D BHR tool is able to generate pulses and receive interface reflections over a distance of tens of meters in electrically highly resistive media such as oil sands. Added to this is the ability of the patented

3D BHR tool to image full 3D structure through its directive properties and circumferential measurement pattern. In this way, the 3D orientation of SAGD wellbores, connected formation contacts, faults and fractures can be determined.

Besides measuring-while-drilling (MWD) and measuring after drilling, the

3D BHR tool can also perform time-lapse measurments for monitoring and act as logging tool. This makes the BHR a very versatile tool, eliminating the need for many other time-consuming and expensive multiple logging runs.

Measuring and imaging with

3D BHR has the advantages over (micro-)seismic imaging that mechanical noise does not affect BHR measurements and that coupling effects are less relevant. The latter makes measurements much more repeatable in challenging operational conditions. Application of the tool is straightforward by inserting the

3D BHR in the borehole and recording in logging mode. Tubed/coiled logging may be necessary in SAGD boreholes

The imaging capabilities of the BHR set it apart from dedicated MWD tools that do logging and automated interpretation only. Full radargrams with reflections and transmissions provide a complete image around the borehole, including adjacent wellbores and pre-existing/induced fractures. In terms of monitoring, steam/water fronts and oil presence/displacement can be differentiated from the background and traced in their movement. This can be considered the dynamic part of oil presence. The static part of oil presence is measured by the

3D BHR as logging tool, through electric attenuation in radar reflection and transmission. From the attenuation, reservoir resistivity/conductivity is logged indicating resistive oil-volumes.