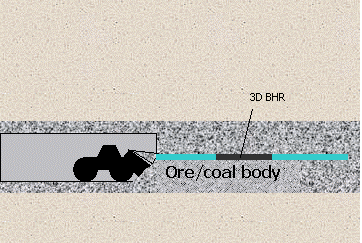

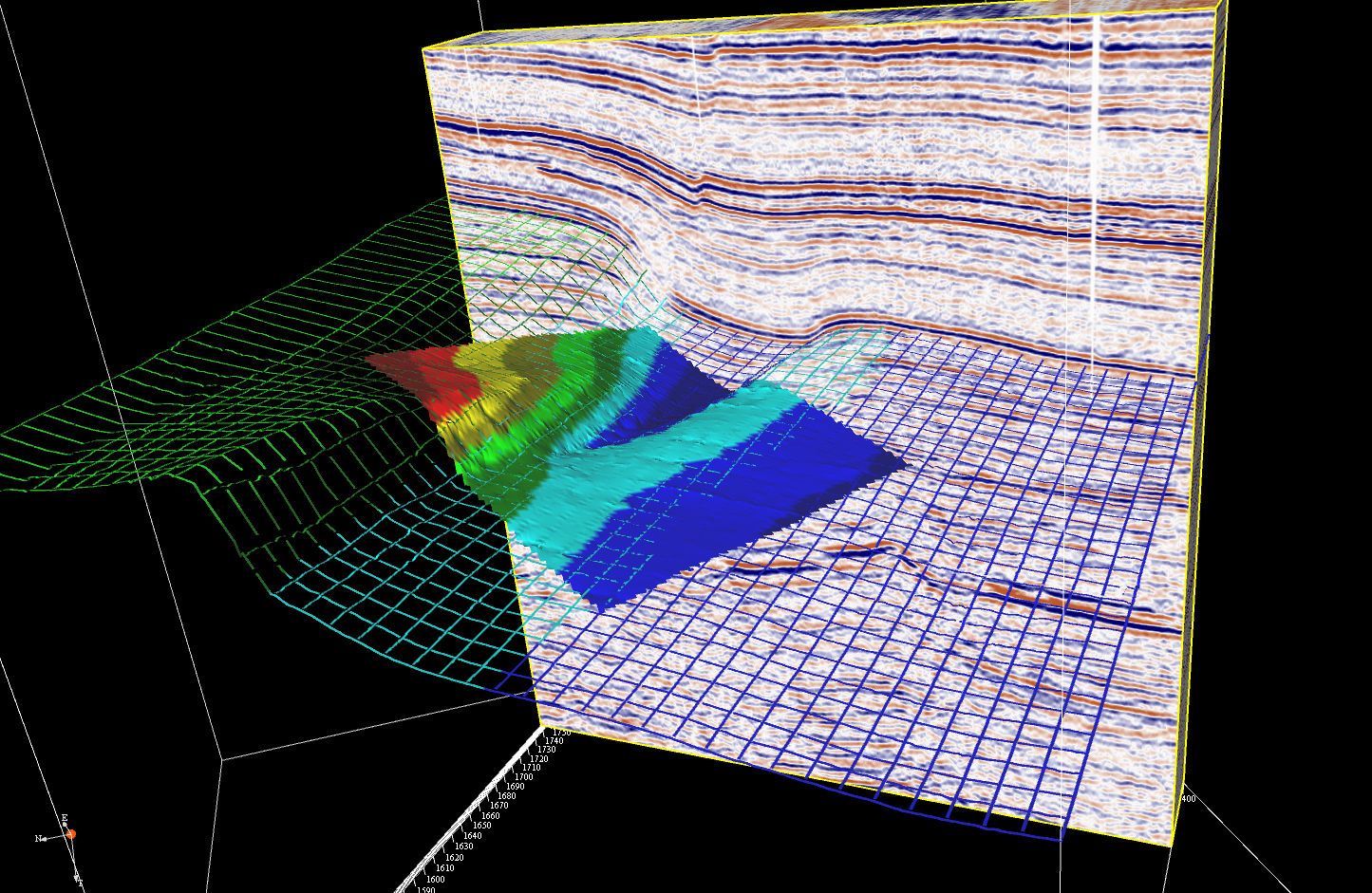

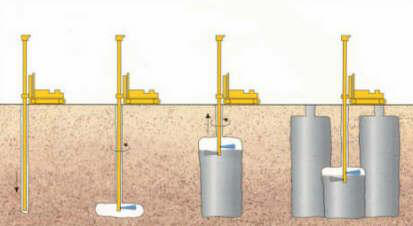

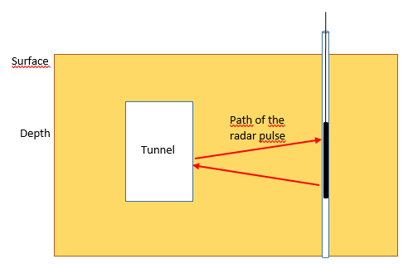

The TISA 3D Borehole Radar is a geophysical technique for high-resolution 3D mapping of the surroundings of a borehole. Applied in a single borehole, this technique combines all the advantages of GPR tools in one piece of equipment: high-resolution data with directional information and a penetration range of up to 15 meters.

The TISA 3D Borehole Radar is a geophysical technique for high-resolution 3D mapping of the surroundings of a borehole. Applied in a single borehole, this technique combines all the advantages of GPR tools in one piece of equipment: high-resolution data with directional information and a penetration range of up to 15 meters.